CB4800 Small Hardware Ornaments Special Water-based Roller-coated Stoving Paint

Name: Water-based Roller-coated Stoving Paint

Catalog: Waterborne Metal Coatings (Baking Type)

Model: CB4800

Hardware industrial products surface spraying treatment is an important method to protect products.Good painting protective layer can reduce the damage of products, make products in good shape, and become a barrier to inhibit the invasion of corrosion medium.

CB4800 can not only play a decorative role, make the product more beautiful, glossy and brilliance, but also protect the product, so that the product is not easy to rust, improve wear resistance, and life extension. CB4800 Small Hardware Ornaments Special Roller-coated Water-based Stoving Paint, can be adjusted into various colors according to customers’ requirements, and has strong toughness, with heat resistance, wear resistance, bending processing resistance and boiling resistance, is a high-quality coating.

The tested workpiece is shown as below (aluminum lantern rivets)

(This aluminum lantern rivet has no cracking in the paint film during the nail pulling process, and has excellent adhesion and bending resistance)

Characteristic

1.Environmental friendly, low toxicity, no odor, low VOC content, no benzene, toluene and xylene and other organic solvents.

2.Can be directly diluted with water, which is safe and completely solves the safety hazards caused by organic solvents.

3.Easy to operate, water can be used to clean tools and contaminants.

4.The painting layer has the advantages of excellent adhesion and bending processability, and excellent boiling resistance.

Use

This product can be widely used in the decoration of the surface of various small hardware products, such as rivets, zippers, buttons, etc.(The products pictures are as below)

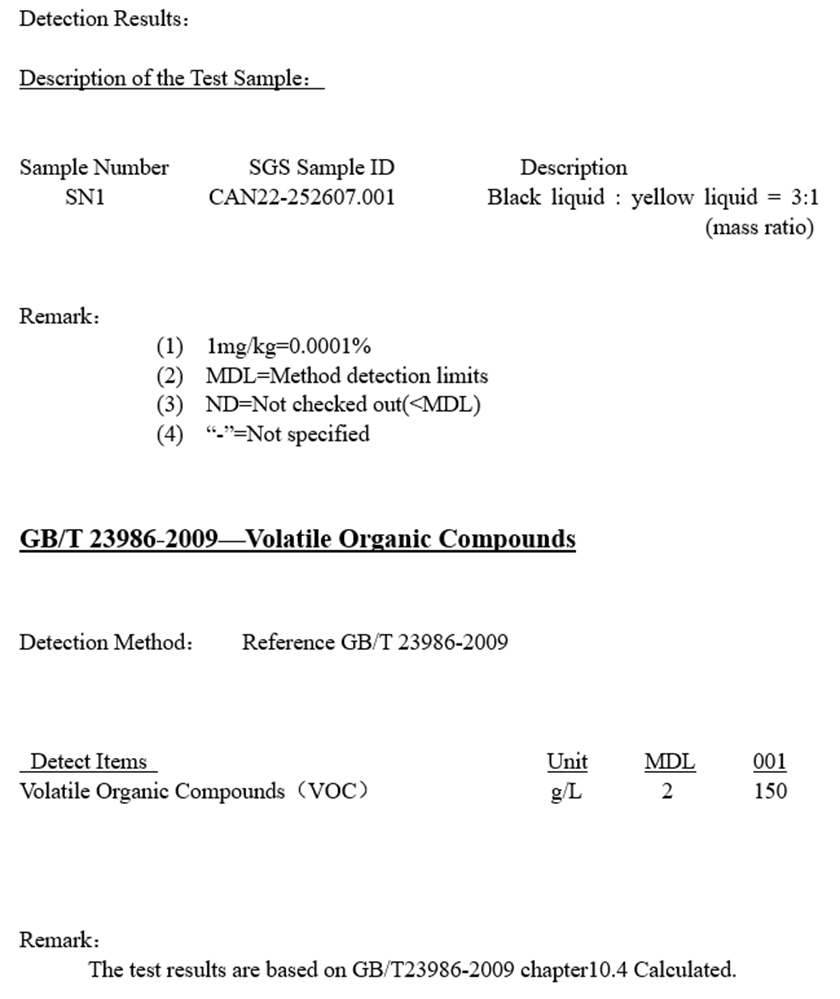

Inspection Report

Sample Picture

Group A Physicochemical Properties

The physical state is a viscous liquid, with a special resin odor, density 1.20-1.40g/cm3 (20℃),

Soluble in water, water can be added when used, and can be adjusted into various colors according to customers’ requirements.

Group B Physicochemical Properties

The physical state is a viscous liquid, with a faint amine smell, the color is light yellow, density 1.15-1.20g/cm3 (20℃), soluble in water, water can be added when using.

Both A/B groups of products do not contain banned aromatic compounds, ozone-depleting compounds, organotin compounds and carcinogens.

Main Technical Indicators and Parameters

| Project | Index |

|---|---|

| Appearance, Group A | Various colors of viscous liquid |

| Appearance, Group B | Light yellow transparent liquid |

| Drying Time (90℃), min | ≤40 |

| Mixing Ratio, A:B | 3:1(Weight ratio) |

| Applicable Period, h | ≥3 |

| Hardness, h | ≥2 |

| Adhesion, Grade | ≤1 |

| Flexibility, workpiece T bend 180° | Pass |

| Impact Resistance, cm | ≥50 |

Construction Process

1. During construction, the A and B components are first mixed evenly according to the proportion, and 10~30% ionized water or tap water can be added to dilute according to the viscosity, and then used after 10 minutes of curing; This product is a two-component coating, and the applicator should use it as needed to avoid waste.

2. Construction Method: roller coating.

3. Procedure:

(1) Firstly, weigh the appropriate amount of small hardware to be processed, pour it into the drum, and then start heating slowly.

(2) When the temperature of the workpiece reaches 90℃, operator can start to control the spray gun for construction, During spraying, the oil output of the spray gun should be adjusted in time accordingly to ensure the workpiece can be evenly oiled.

(3) A pot of workpieces generally needs to be sprayed for 30~40 minutes, and the operator needs to control the progress of construction.

We insist on using our own professional attitude, paying attention to the every inch of our products, and innovating continuously.